1.Efficient Mixing and Shear Heat Control Capability

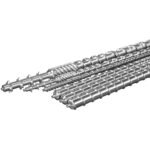

The key features of Harden’s conical twin screw and barrel design include excellent mixing capability. Its structure provides a larger screw surface area, enhancing the mixing and shearing effects of the material, resulting in better plasticization and uniform mixing. This helps to evenly disperse additives, pigments, fillers, and other materials within the plastic matrix, improving color consistency and performance of the finished product. The design of Harden’s conical twin screw and barrel effectively reduces the generation of shear heat by reducing the frictional area between the material and the screw. This helps to prevent overheating and degradation of the plastic, ensuring the quality and performance of the material. These designs offer precise flow control, ensuring uniform flow and distribution of the plastic material during processing. This helps to reduce defects and improve the surface quality and appearance of the products. Harden’s conical twin screw and barrel have excellent temperature and pressure control capabilities, resulting in stable and controllable processing parameters. This contributes to improved production consistency, repeatability, and reduced variability and waste during the production process.

2.Versatility

Harden’s conical twin screw and barrel can be custom-designed to meet specific processing requirements, catering to different types of plastic materials and products. This versatility makes them suitable for a wide range of applications and processing techniques, including both rigid and flexible plastics. Whether it’s PE, PP, PVC, or PS, the conical twin screw and barrel can deliver excellent processing results and product quality. They can adapt to diverse processing needs and are used in the production of various plastic products, including pipes, sheets, profiles, films, and injection-molded parts.

Reviews

There are no reviews yet.