Product Description:

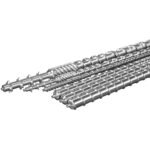

1、Customized Design: We can design screw structures based on customer requirements and their configurations, assisting them in improving product output and achieving better plasticization. Our professional team will collaborate with you to ensure that the design of the screw and barrel aligns perfectly with your specifications.

2、Premium Materials and Three-Surface Alloy Process: We utilize high-quality materials, such as 38CrMoAla or 42Cr, to ensure excellent wear resistance and corrosion resistance of the screw and barrel. Additionally, we employ advanced three-surface alloy processes, including base diameter alloy, flight alloy, and flight lead angle alloy, to provide extended service life and enhanced stability in performance. These processes guarantee the screw’s high wear resistance, excellent corrosion resistance, and temperature stability, enabling it to maintain exceptional performance during high-speed extrusion processes.

Reviews

There are no reviews yet.