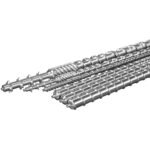

1、Alloy Coating and Chrome Plating Processes

The blow molding screw undergoes alloy coating to enhance its wear resistance. After manufacturing, chrome plating is applied to create a hard surface coating, further increasing its durability and lifespan. This coating reduces wear caused by high temperature and pressure during plastic extrusion, maintaining the screw’s smoothness. It also forms a corrosion-resistant layer, protecting against chemical damage. The smooth plating surface prevents adhesion and blockages, making the screw easier to clean and maintain, resulting in improved plastic material processing.

2、Materials and Precision in Processing

We use high-quality materials like 38CrMoAla or 42CrMo and employ automated CNC processing for the Harden blow molding screw. Our skilled inspection team ensures precise measurements of parameters such as straightness, diameter, and pitch. This guarantees a uniform and defect-free surface, maintaining the product’s smoothness, brightness, and thickness.

Reviews

There are no reviews yet.